Plywood Cold Press-manufacture,factory,supplier from China

(Total 24 Products for Plywood Cold Press)

Hydraulic Hot Roller Press MachinePlywood hot press machine is used for the final formulation of plywood, it is the most important machine in plywood production. Hot press machine is one of the most important machines in plywood production.

Contact Now

Wood Plywood Cold Press MachineThe hydraulic press applied to plywood is also called plywood pre-press and plywood cold press. The cold press is also a kind of plywood machine. It is mechanical equipment to shorten the hot pressing cycle and improve the quality of the board. The cold press is a pressure machine. The cold press machine mainly performs a short-time cold press on the veneer after the glue-coated assembly blank, so that it is initially formed, and then sent to the hot press for the process of hot pressing and gluing.

Contact Now

Plywood Wood Cold Press Laminate MachineThe cold press is also a kind of plywood machine. It is mechanical equipment to shorten the hot pressing cycle and improve the quality of the board. The cold press is a pressure machine. The cold press machine mainly performs a short-time cold press on the veneer after the glue-coated assembly blank, so that it is initially formed, and then sent to the hot press for the process of hot pressing and gluing. It is an important piece of equipment to improve the quality of plywood, and it is also an mportant link.

Contact Now

Woodworking Hot Press Machine For PlywoodPlywood hot press machine is used for the final formulation of plywood, it is the most important machine in plywood production. Hot press machine is one of the most important machines in plywood production.

Contact Now

Hydraulic Veneer Hot Press Machine For PlywoodHot press machine is one of the most important machines in plywood production. It determines production efficiency and the quality of final products.

Contact Now

Plywood Hydraulic Hot Press Machinery Plywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

Wood Laminate Hot Press Machine For PlywoodPlywood hot press machine is used for the final formulation of plywood,it's most the maximum critical machine in plywood production.hot press machine is one of the maximum important machines in plywood production.it determines production efficiency and the nice of final merchandise.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts.extensive range of procedure parameters adjustment control system,affordable design to fulfill diverse pl

Contact Now

15 Layers Industrial Wood Machine Hot Press MachinePlywood hot press system can press veneers together with excessive temperature.that's used in furniture and synthetic board secondary operation. guide and automated controls make the hydraulic press quicker, greater precise, and greater convenient for global customers to apply.our warm press is ready with a microcomputer manage device for each guide and automated manipulate.

Contact Now

Automatic Hot Roller Press Machine For LaminatesPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

Wood Hot Press Machinery PlywoodHot press machine is one of the most important machines in plywood production. It determines production efficiency and the quality of final products.

Contact Now

Wood Veneer Roller Press Dryer MachineVeneer dryer is one of important auxiliary equipments in large-scale plywood production line, and help you to improve productivity and reduce cost.The moisture in the veneer affects the total drying time. For example, the difference in moisture content of the heartwood of redwood from different logs may be as much as 2 to 1. The wetter heartwood veneer requires significantly longer drying time than drier heartwood of the same species.

Contact Now

Hydraulic Hot Press Machine For PlywoodPlywood hot press machine is used for the final formulation of plywood,it is the most important machine in plywood production.Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process r

Contact Now

Woodworking Hot Press Plywood Machine For WoodHot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requirements.Product parametersTotal pressure500tonsBoard feeding directionFrom the long sidePressure0-25mpaHot Press Pl

Contact Now

Multilayers Hot Press Wood MachinePlywood hot press machine is used for the final formulation of plywood,it is the most important machine in plywood production.Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requir

Contact Now

Wood Laminate Veneer Hot Press MachinePlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation.Manual and automatic controls make the hydraulic press faster,more precise,and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.With a simple push of a button you can control a whole set of processes including pressing plate ascending,closing, pressure adding, pressure maintaining,timing and pressing plate descendin

Contact Now

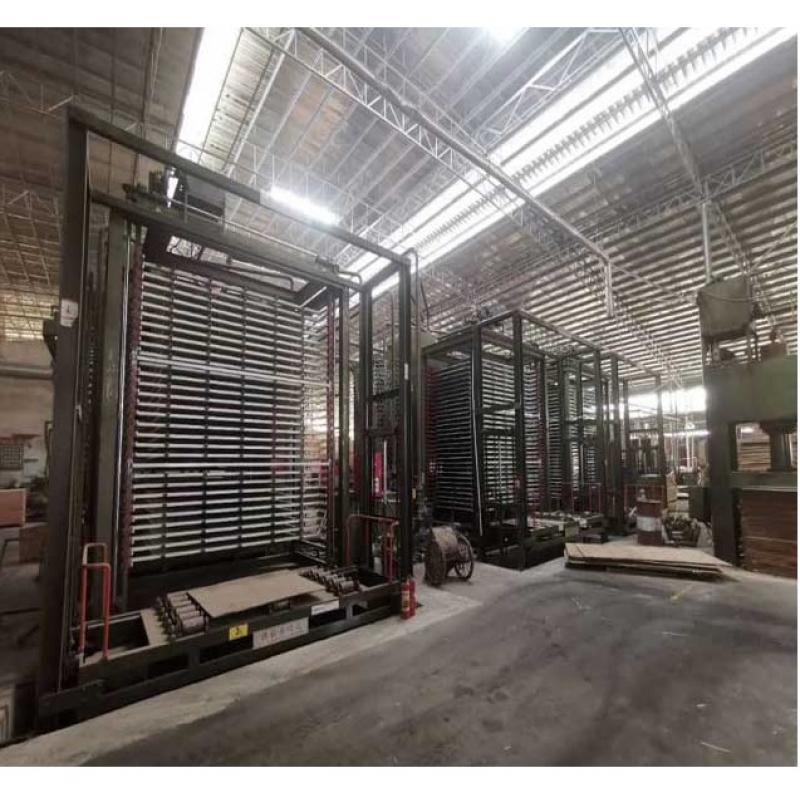

Vertical Core Veneer Dryer Press MachineVeneer Dryer Machine is renowed for consistently producting and high quality veneer with a uniform dry moisture content.Veneer Drying Machine offer the highest efficiency,save energy,reduce cost and environmental friendly.By adopting latest international pressure contact veneer drying technology.Roller veneer dryer has the advantages of simple operation,safety and practicality,stable operation and easy maintenance.Integrated design of the veneer dryer can greatly improve the utilization rate of the space occupied.The veneer enterprises can do the drying

Contact Now

Wood Laminate Veneer Hot Press MachinePlywood Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system, heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requirements. Product parametersTotal pressure500tonsBoard feeding directionFrom the long sidePressure0-25mpaHot P

Contact Now

Plywood Peeling Knife is a high-precision tool designed for the wood processing industry, widely used in veneer production, wood surface treatment and other fields.

Contact Now

Woodworking Hot Press Machine For VeneerOur Hot press machine low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requirements. Product parametersTotal pressure500tonsBoard feeding directionFrom the long sidePressure0-25mpaHot Press Plate Size2700*1370*40mm double inlet and outletCylinder diameter and strokeΦ360x2, 1050mmFrameBolt connectedLayer number15 layersLayer space70mmhot press plate number16total power20.5kw

Contact Now

Hot Pressing Laminating Press Machine For WoodPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

Automatic Hot Press Woodworking Machine for VeneerPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

Laminate Hot Press Veneer Machine For WoodPlywood hot press machine is used for the final formulation of plywood,it is the most important machine in plywood production.Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production proces

Contact Now

Wood Laminate Hot Press Woodworking MachinePlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Contact Now

Continuous Veneer Hot Press Dryer EmissionsVeneer dryer Machine is one of important auxiliary equipments in large-scale plywood production line, and help you to improve productivity and reduce cost.The moisture in the veneer affects the total drying time. For example, the difference in moisture content of the heartwood of redwood from different logs may be as much as 2 to 1. The wetter heartwood veneer requires significantly longer drying time than drier heartwood of the same species.

Contact Now

Relate News

Over the last 3 days, we finished loading the roller dryer parts to the 4 containers. The roller veneer dryer is customized according to the customer's special requirement. The working width and number of the heat exchangers are customized for the customers in the very cold area.

There are two traditional heat sources for the veneer dryer, namely, steam boiler and thermal oil heater. The advantages using these two heat sources are one machine can provide heat for more than one veneer dryer. Typically, in a large plywood plant, one big capacity steam boiler or thermal oil heater can supply sufficient heat to several veneer dryers, hot press machines, etc. Only one heat source or heat energy center is enough. The disadvantage is the operation cost will be very high like the fuel cost.

Veneer dryer is one of the main equipment in the production process of veneer and plywood, and the drying quality of veneer directly affects the quality of veneer and plywood products. The principle is that the veneer is preheated and dried under the clamping of the upper and lower two coils, and the coil is heated by steam or heat conduction oil to transfer the temperature to the veneer.

Roller Veneer Dryer is one of the most often used veneer dryers for drying core veneer in the plywood making process. After peeling, the fresh veneer is fed into the core veneer dryer. Through the press of the upper rollers and heating of the hot air sections, veneer is delivered to the cooling section and finally discharged at the outfeed of the veneer dryer. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

The four deck veneer dryer purchased by myanmar factory is used to dry rubber wood. The customer gives good feedback. It is used with the biomass burner.The biomass burner which as the heat source can provide high temperature to the dryer to make sure the sufficient heat impinged on the wet veneer in an efficient manner. At the same time, the tree bark from debarker and waste veneer from peeling lathe were burned as the fuel directly, which solved the waste accumulation in the veneer plywood making factory.

Wood-based panel is wood or other non-wood plants as raw materials, after a certain mechanical processing separated into a variety of unit materials, with or without the application of adhesives and other additives glued board or molded products. It mainly includes three categories of products, such as plywood, particleboard and fiberboard, and its extended products and deep processing products reach hundreds of kinds. The birth of wood-based panels marked the beginning of the modern period of wood processing.

The 2deck veneer roller dryer order is expected to be ready on June 5th, 2023. We will load containers on the date approved by the customer in Zimbabwe.

The 2 deck roller veneer dryer working width 3750mm heated with thermal oil. This first shipment will be trucked to the customer's factory tomorrow on April 7th, 2023.

Daily maintenance of veneer dryer1. During normal use,the lubricating oil should be replaced after the fan runs for 72 hours to ensure the normal operation of the fan.2. When starting the equipment,it should be heated first,and then the fan should be turned on.We can't just heat without turning on the fan.3. If the heat sink is blocked by foreign matter,it should be cleaned in time, otherwise the heat transfer will be affected.4.

Recently, the 2 deck veneer dryer purchased by our customers has been installed. Our engineers went to guide the installation and will return only when the equipment is operating normally. Equipped with a biomass burner, it can directly burn bark to save fuel costs. We welcome customers to visit the customer site to inspect the drying equipment.The roller veneer dryer is a new generation of wood veneer drying equipment. It uses the latest international pressurized contact veneer drying technology.